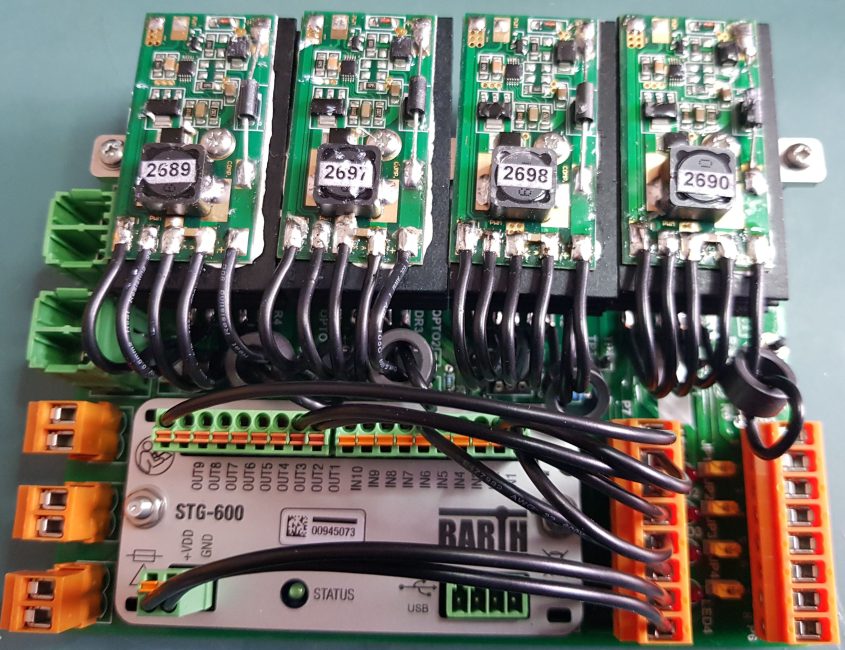

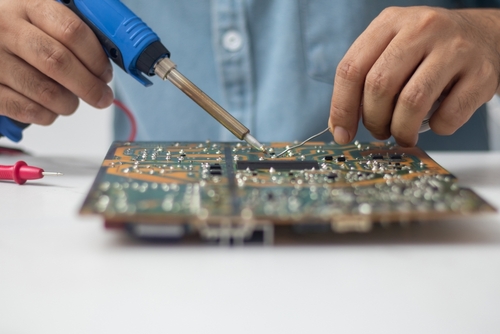

Assembly Services

Our in house electronic assembly services are geared up for small volume manual electronic assembly of through hole and low density surface mount parts.

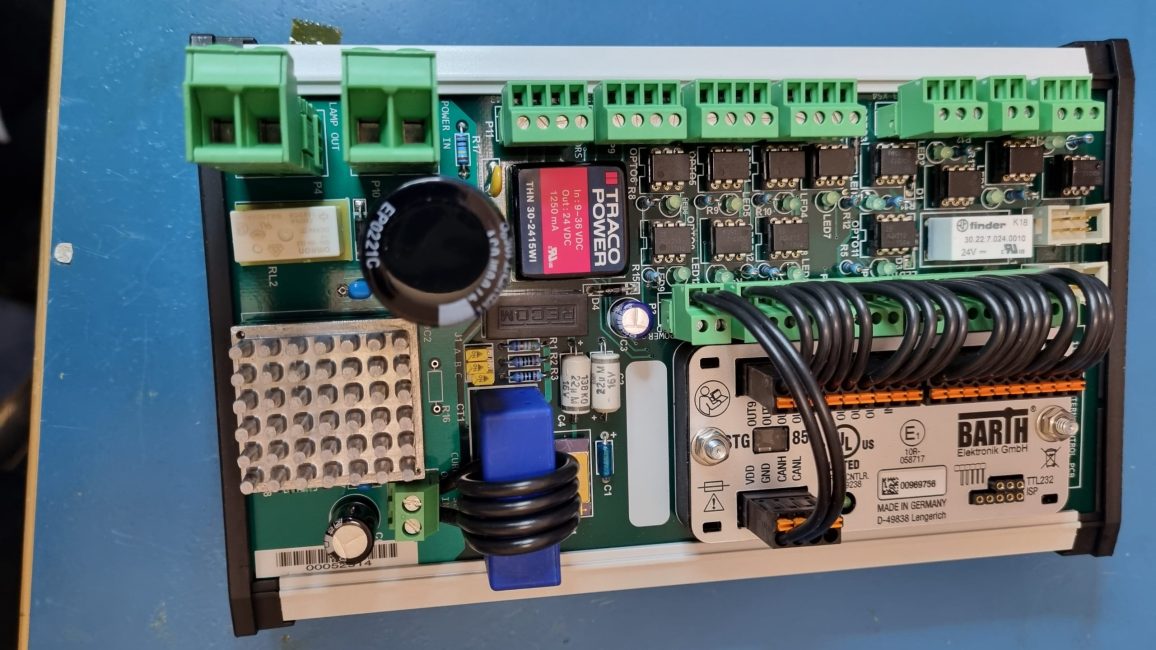

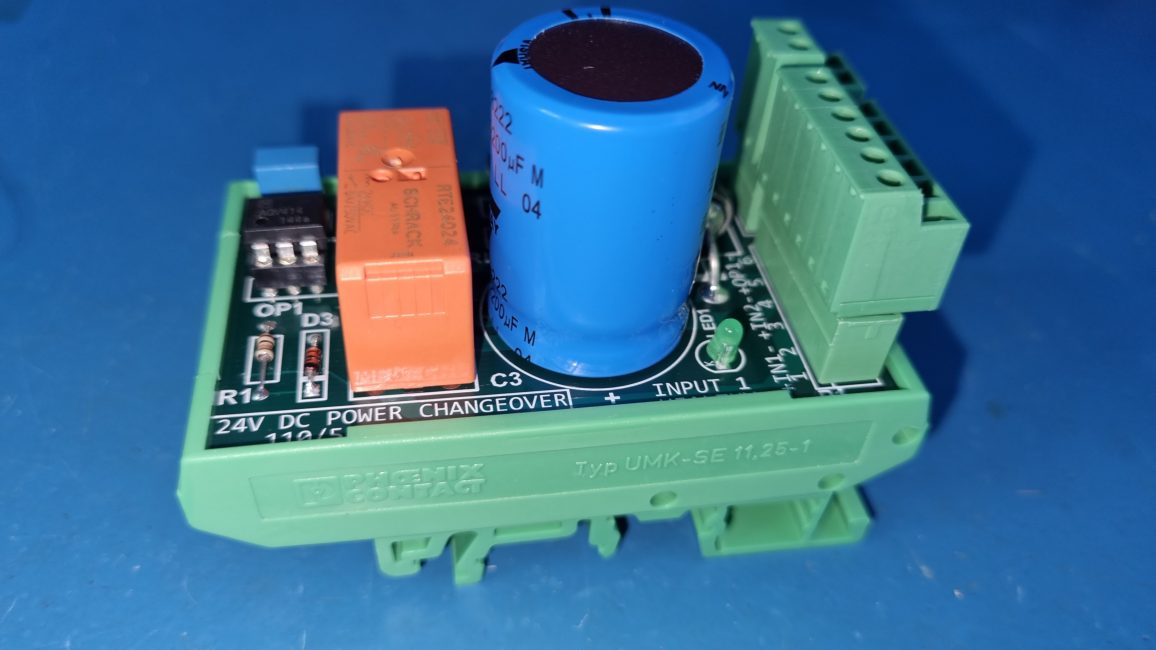

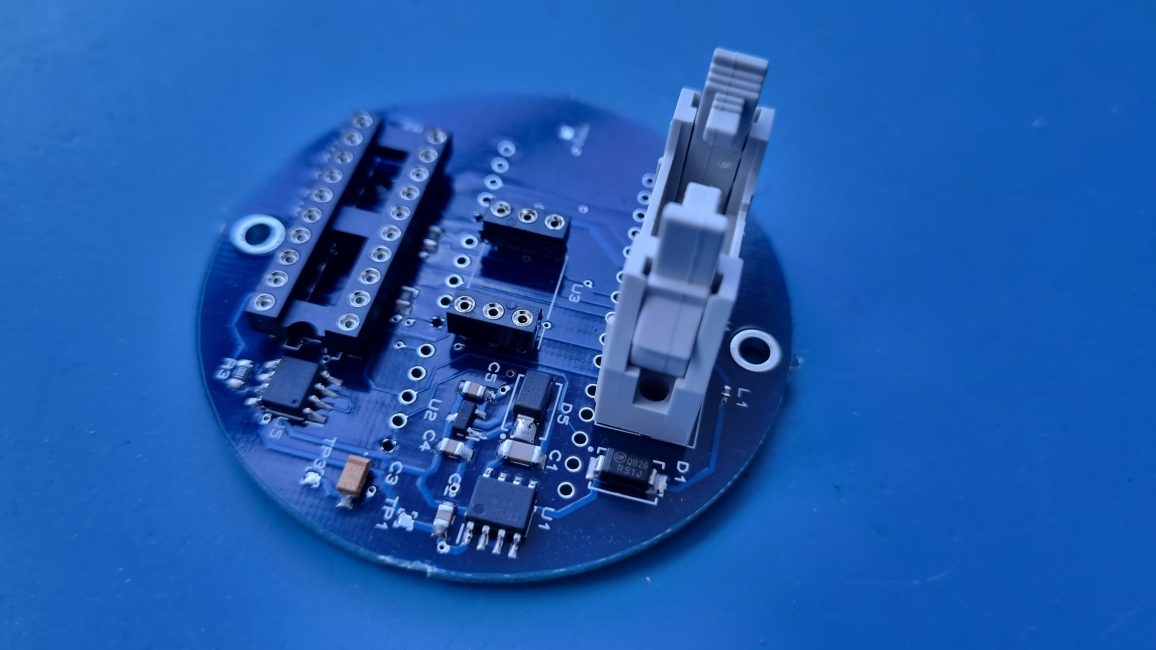

Electronic Assembly

Depending on the size and complexity of the build our typical build quantity is 20 units or fewer. For small boards with few parts then we may build higher volumes than this.

For initial prototype builds we are more than happy to build one or two units to enable the client to test their product.

For higher volume requirement we can recommend sub contractors if required.

Our Process

From the information that the client gives us we will produce a Bill of Materials for your job.

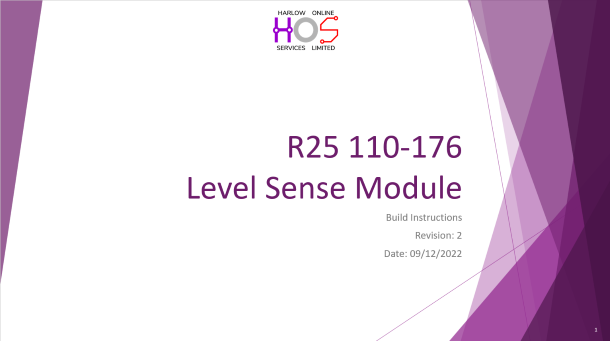

We will then study the build requirements and produce a ‘Production Guide’ for your product. This will instruct our team on how to build your product from fitting the components correctly, the order in which parts are fitted etc. If the client has any particular requirements during the assembly this will be documented here.

This will enable us to raise a Manufacturing Work Order and job sheet for your build.

Purchasing

Once this is all in place our Purchasing team will procure the components required for your job.

All orders are placed with suppliers from our approved supplier list to comply with the requirements of our ISO 9001:2015 certification.

As parts are received they are added to the ‘kit box’.

Production

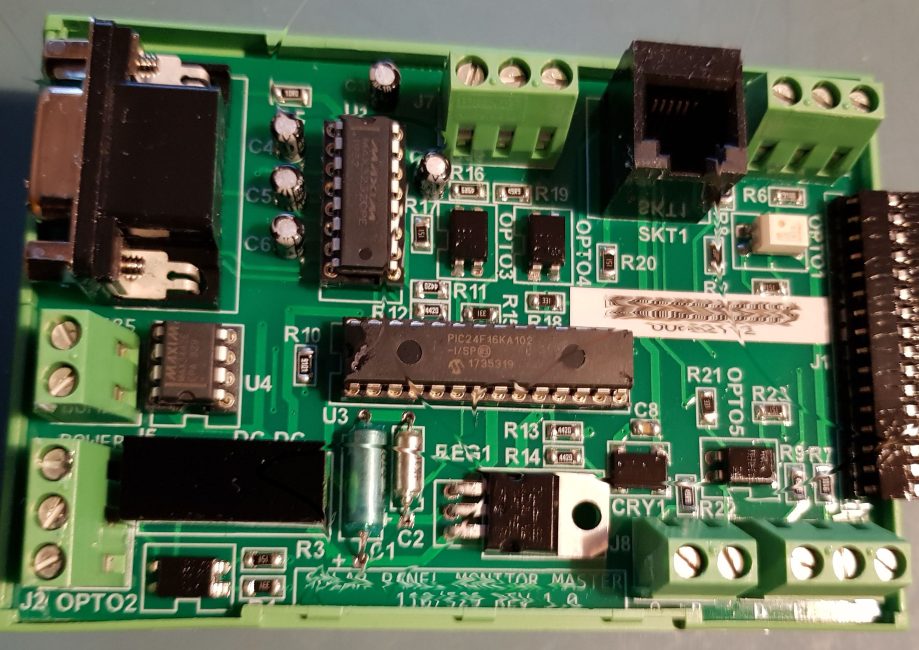

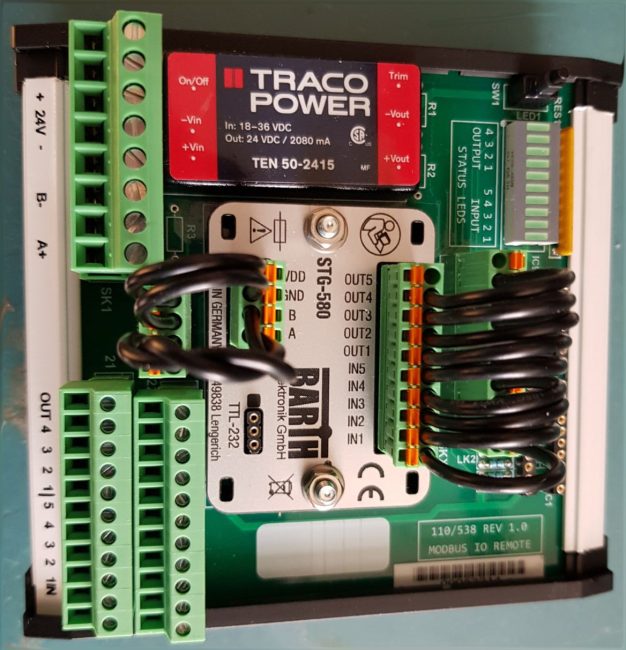

When all the required parts have been received the assembly will then take place.

Each item is built using the ‘Production Guide’ document.

Completed boards are given a unique serial number which links back to a Manufacturing Order and Bill of Materials so that we can track its history and parts.

Post Production

After production boards are typically cleaned to remove all fluxes from the circuit boards and components. Typically we use water soluble solder fluxes on our boards so these are simply washed with deionized water.

All items are then visually inspected to ensure that they meet the required specifications.

Any functional or additional testing can be specified by the client to meet their needs.

Typically a 24 month warranty is provided on all assemblies.

At the end of Production the circuit boards are securely packaged and dispatched to the client via and approve Courier.

Modifications and Repairs

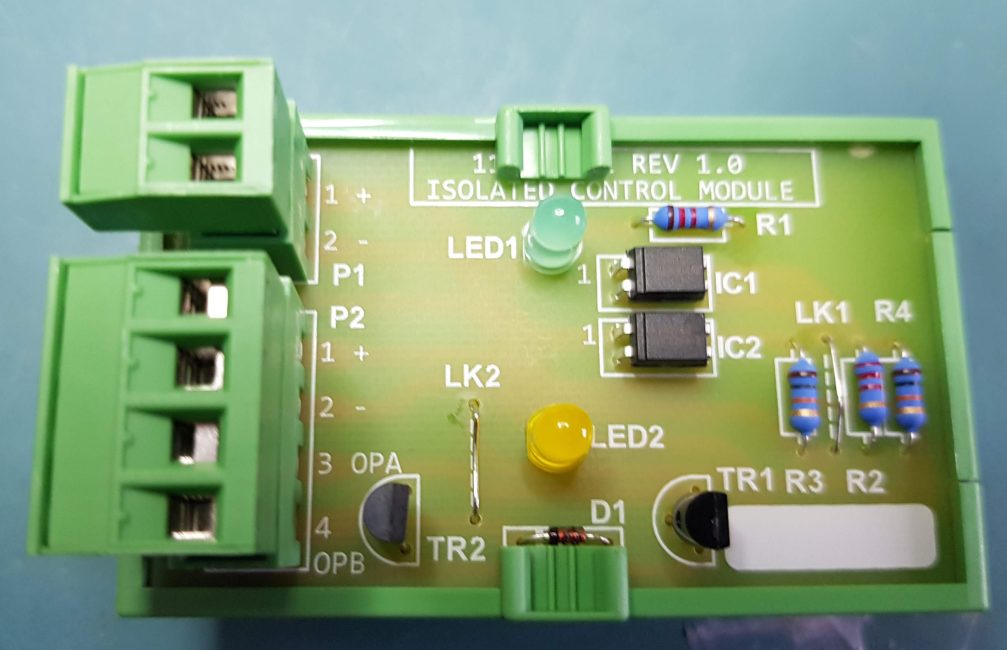

While full build assembly is our preferred service we do offer services to modify and or repair electronic circuit boards.

This is usually done on a one-off basis so please contact us to discuss your requirements if this is a service that you wish to use.

Typically this service will use a subset of our Assembly procedures.

All electronic assembly work is carried out within the terms of our ISO 9001:2015 certification.